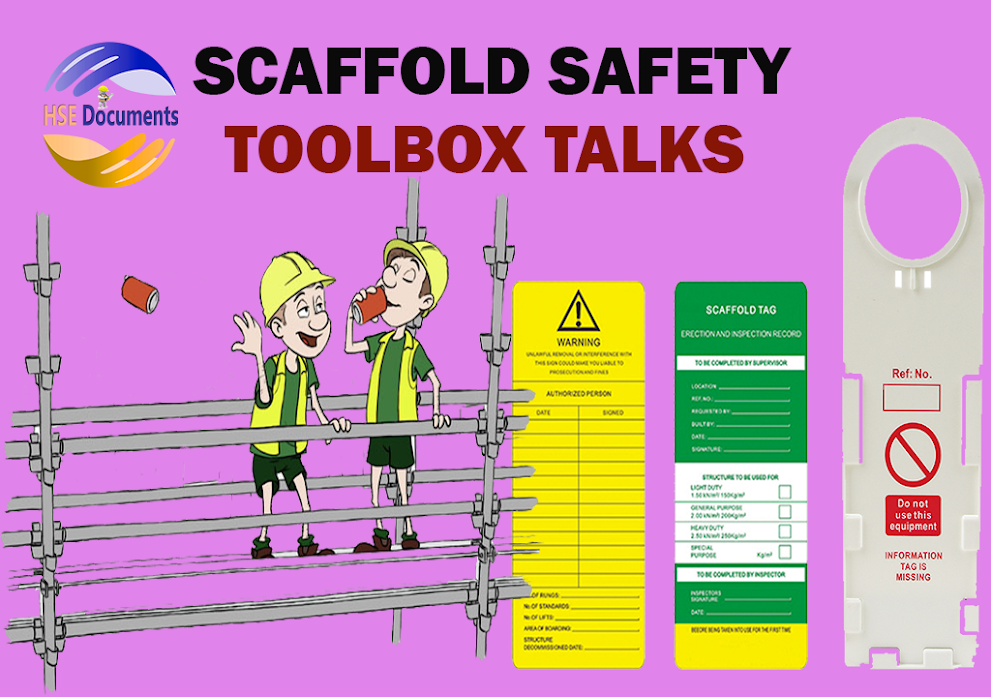

Supported Type Scaffold Safety

An Overview of Scaffold Safety

What Topics to be Covered in the Attached Training PowerPoint File:

Scaffold hazards

- Duties of a “competent person”

- Basic scaffold requirements

- Fall protection and guardrails

- Employee training

- Hazards of Scaffold Work

According to the Scaffold Industry Association (SIA), the five most serious & fatal scaffold hazards are:

- Falls

- Unsafe access

- Falling objects

- Electrocution

- Scaffold collapse

- Falls, scaffold collapse and electrocution account for most scaffold related fatalities.

- A combination of regular inspection and consistent training of workers can go a long way to reducing these risks.

Supported Type Scaffold Safety

.png)

.png)